Evaporator Coil Efficiency

A Dirty Coil Costs Money

A Dirty Evaporator Coil will cost you money. Proper airflow across your Evaporator Coil (indoor air conditioning coil) is necessary to maintain the efficiency of your air conditioning and heating system, which translates into dollars saved. Several component conditions of your system can negatively affect air flow,

- Dirty Evaporator Coil

- Dirty Air Filter

- Speed of Your Indoor Blower Motor

- Cleanliness of the Indoor Fan Squirrel Cage

- Return Air Duct Size and Access

- Supply Air Duct Size and Access

- Supply Air Diffusers are blocked by furniture or other items

- Ducts are partially or fully disconnected

Proper Air Flow

Proper air flow is something we understand in areas of our life that are not related to heating and cooling our home. If you take a piece of cardboard and cover the inlet side of your vehicle radiator on a 100* day, what will happen when you take it for a ride…your engine will overheat. Place your finger on one side of your nose and close off the nostril, keeping it depressed for two minutes and what will happen…you will continue to breathe with extra effort on your part. Just as a room fan with a towel thrown over it will not blow air, reduced air flow affects cooling. These examples illustrate how a dirty evaporator coil does not allow proper air flow.

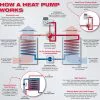

Conventional residential air conditioning removes heat from your house and transfers it to the air outside by using the pressure and temperature qualities of refrigerant in the system. The compressor, outdoor condensing coil, and indoor evaporator coil work together as a team to bring cool comfort to your house. Inefficiency in any of the three components affects the entire system, and increases your energy costs.

Dirty Evaporator Coil and Cooling Performance

Optimum cfm (cubic feet per minute) air flow across a residential cooling coil is in the 350 cfm to 450 cfm range per ton of cooling. A study conducted by the Florida Solar Energy Center in 27 installations “Measured air flows ranged from 130 to 510 cfm per ton (17.5 – 68.5 L/S per kW) with an mean of 320 cfm/ton (43.0 L/S per kW).” The study can be read online at the following link, http://www.fsec.ucf.edu/en/publications/html/FSEC-PF-321-97/. Evaporator air flow is a common problem affecting a large percentage of homes that do not have regular maintenance performed by a qualified professional.

There are many technical reasons why reduced air flow costs money and reduces system life. If you are interested in knowing more about superheat, subcooling, saturation temperatures, sensible heat, latent heat, compressor efficiency, and properly designed duct systems, please contact me at [email protected]. If your interest is comfort and savings, schedule an appointment to tune-up your system by calling (417) 352-0975 or make an appointment on-line.

Professional maintenance for your heating and cooling system will normally be less than $200.00 a year per complete system. Well maintained heating and cooling equipment will be more reliable, have a longer life, is good for the environment, and should pay for itself in utility cost savings.